Did you ever speak to your switchboard design team whether they are considering the panel location and environmental conditions when selecting the sheet metal enclosures for your Switchboards? Whether you are using Unibody or Modular enclosure, this is an important question.

Take a little time to read below

Basic environment conditions that should be considered when selecting the correct enclosures for switchboard solutions.

- Location of Installation – Indoor or Outdoor/ Salinity/level of corrosion accelerating agents

- Maximum and Minimum ambient temperature

- Ambient Humidity

- Seismic level

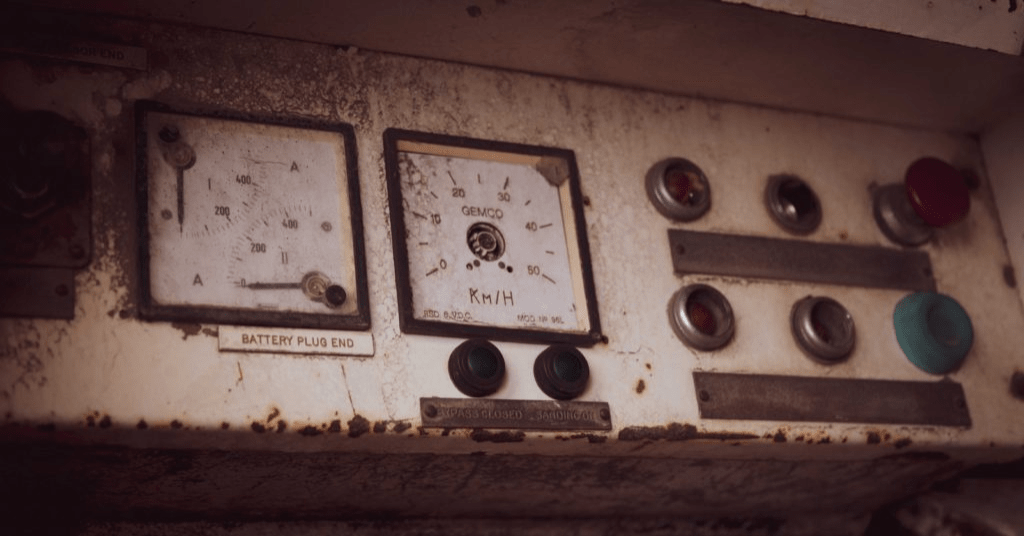

In this instance we only consider the importance of identifying the location of installation which could be a main reason for the risk of corrosion damages. In the initial stage, corrosion marks will be only an aesthetic issue but if you delay corrective action this will result in a major breakdown, corrosion penetration rate will depend on the level of exposure

How to identify the Exposure level.

In ISO 12944-2, different exposure conditions are defined as C1-C2, C3, C4, C5-I and C5-M

For Interior Applications

- C1-C2: Inside a building with an atmopher with very low corossivity.

- C3: Industrial enviornments with moderate risk of corrosivity (So2 and Cl)

- C4: Chemical processing plants, Water treatment plants etc

( High content of SO2, Cl..etc)

For Exterior Applications

- C1-C2 : Low poluted, Dry areas

- C3 Urban and industrial atmospheres, Moderate SO2 pollution, Costal areas with

Moderate Cloride content

- C4 Industrial and Coastal Areas

- C5 I Industry with high humidity and aggressive atmosphere

- C5 M Marine coastal, offshore enviornments with High salinity

After identifying the location and environment conditions, an expert switchboard manufacturer will be able to select suitable;

- Base metal

- Type of Paint / Type of Paint Primer

- Number of coatings

- Thickness of the each layout

- Paint Curing plan.

- Maintenance intervals for enclosure

Further, if your enclosure supplier is an expert in surface coating, he will possess calibration reports of the paint curing system with temperature profile curves, maintenance reports of treatment chemical system, daily test samples, etc. it is very important to test treatment chemical samples and coated samples frequently, test frequency will depend on the load and number of color changes. Some manufacturers follow more advanced guidelines in testing, to ensure the quality of the product.

Cross hatch test, Conical bending test, Impact test and Cupping test are basic and important tests that are conducted frequently to test powder coating sample sheets.

As a responsible switchboard assembler, it is very important to verify whether your enclosure supplier is qualified to provide the correct enclosure for different environment conditions.

None of your customers are willing to place their valuables in an unsafe locker!!!